Application Examples

Various solutions and application examples that are utilizing Reed Switches or Reed Sensors - learn more and get inspired!

Position Control

To check the (end)position of a mechanical part of the application.

Washing Machine

A magnet attached to the drum activates a Reed Switch when the drum position is correct (lid upside). The Reed Switch gives a closed signal to the control unit to unlock the door.

Often used

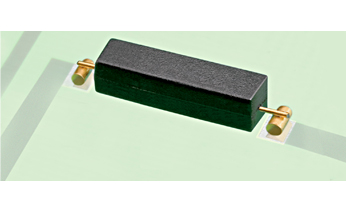

Hydraulic- or Pneumatic Cylinder

Magnetic Sensor based on Reed, Hall or xMR technology are used to detect the (end)position or movement of hydraulic/pneumatic cylinders in industrial automation applications.

Customized housings enable different ways of assembly. LEDs are used to give a visual indication of the Sensors status, and the cylinder position respectively.

Different switching sensitivities and electric properties adjust our Sensors to customers switching distance and voltage requirements. We provide tailor-made Sensor design including individual cable and connector fitting.

Often used

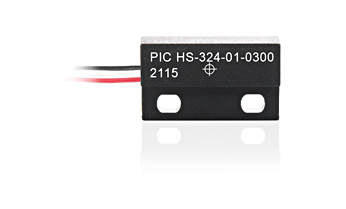

Security Systems/Building Technology

Windows and doors are monitored by Reed Sensors in the windows/doors frame and magnets attached to the window/door. If the window or door is opened with activated security system and alarm is issued.

Another application:

Modern energy saving houses or houses with an open fire place need a security system that enables open fires or working kitchen hoods only when a window is open.

Non-Touch-Switching

Certain functions are switched on or off by using a permanent Magnet and a Reed Switch or Reed Sensor.

Level Sensing

Safe, simple and reliable liquid level detection.

Fluid tanks

Tanks in industrial environments or machines contain operating fluids, lubricants and other crucial materials.

The level of these materials is detected with Level Sensors or special design Reed Switch Chains and matching floats containing a magnet.

Often used

Automatic Coffee Maker

A Reed Sensor integrated into the coffee maker housing is activated by a magnet in a float, floating inside the detachable water tank.

When the water level sinks to a certain height an alarm is issued, no more coffee will be produced to protect the machine from running dry.

Often used

Condensate Dryer

When drying wet clothes in a condenser a huge amount of water remains in the condensate tank. The level of this condensate water is checked with Reed Technology, a warning is issued when the condensate reaches a critical level.

Some dryers have an integrated condensate pump to remove the condensate from the dryer. This pump is also controlled by the Reed Sensor or Level Sensor.

Often usedFlow Detection

Detects the absence or presence of flow in a system and uses the flow to generate a signal.

Speed Measuring (RPM)

Rounds-Per-Minute calculation to obtain speed, mileage and other operational data.

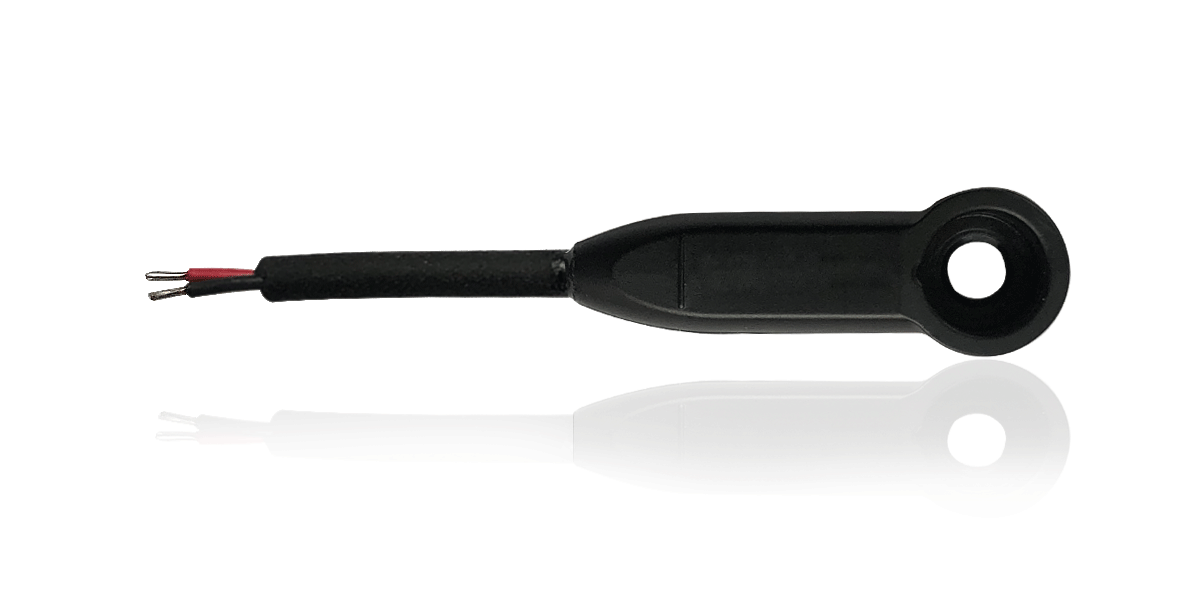

E-Bike Speed and Motor control

Electric motors of e-bikes and pedelecs are supporting the deployed body power in subject to the current speed. The current speed is measured with a spoke mounted magnet and a Reed Switch at the fork.

Each wheel turn activates the Reed Switch, the motor control united counts activations and multiplies them with the wheel diameter. Additional motor power is set free according to the measured speed.

Often used

Bicycle Speed-Meter

To calculate the speed and the mileage when riding a bicycle, a speedometer is used. A spoke mounted magnet activates a Reed Sensors sitting at the fork.

The signal is transmitted to the bicycle computer which calculates speed an mileage with the number of wheel turns (means Reed Sensor activations) and the wheel diameter.

Often used

Windspeed Metering

Modern buildings use automatic blinds to provide shadow and heat protection. These blinds a very prone to fast winds and storms.

A wind meter uses a fan with a magnet and a Reed Sensor to calculate the current wind speed and to automatically draw the blinds up if the wind speed exceeds a certain level.

Often usedAll mentioned applications are just some general examples for the usage of Reed technology. Just get in touch with us - we will develop a specific solution for your sensing needs!