Handling Notes

Useful tipps and background information abour our core technology, different materials and the handling of Reed Switches and Reed Sensors.

Reed Switches

Shock Resistance

Generally Reed Switches provide high shock resistance up to 100 g. Still a drop on a hard surface can generate a shock of several 100 g, which can lead to de-adjustment of contacts. Switches having been dropped should be re-tested for sensitivity before usage!

Do’s and Don’ts when cutting and bending Reed Switches

Incorrect bending or cutting of terminals may lead to cracks in the sealing area due to heavy mechanical stress. To avoid this problem the remaining part of terminal between glass body and point of bending resp. cutting, should be gripped tightly.

Dimensioning of modified Reed Switches

We supply Reed Switches with terminals modified to nearly any requirement.

Level Sensors

Level Sensors are available in Form A- and Form B-Variants.

Form A means that the switch is open when the float is on the bottom of the stem (means tank is empty) and closed when the float is on the top of the stem (tank is full).

Form B means that the switch is closed when the float is on the bottom of the stem (means tank is empty) and open when the float is on the top of the stem (tank is full).

If you need to know if your tank is empty or the liquid reaches a low level (e. g. to refill coolant or lubricant) than a Form B Level Sensor is used.

If you need to kniw if your tank is full or nearly full (e. g. to activate a pump for emptying the tank) than a Form A Level Sensor is used.

Mounting

In general all oour Level Sensors are suitable to be either mounted from top or from the bottom of a tank. If you mount a Level Sensor from the bottom, with the stem directing up, the switching behavior will change (Form A will become Form B and vice versa).

Explore our Level Sensor Products

Housing material

Our standard housings are made from ABS, PA (Polyamide), PP (Polypropylene), nickel plated brass or stainless steel. Of course we are ready to povide costomized solutions with other materials as well.

| + = Excellent o = Limited - = Poor | Chemical resistance @20°C / @60°C | ||||

| ABS | PA | PP | POM | Stainless Steel 304 | |

|---|---|---|---|---|---|

| Acetic Acid, dilute | - / - | - / - | + / + | + / o | + / + |

| Acetone | - / - | + / + | + / o | + / o | + / + |

| Ammonium Hydroxide | o / - | + / + | + / + | + / + | + / + |

| Aniline | - / - | o / - | + / + | - / - | + / + |

| Beer, Wine, Whiskey | + / + | + / + | + / + | + / + | + / + |

| Butanol | + / o | + / + | + / + | + / o | + / + |

| Chloroform | - / - | - / - | - / - | - / - | + / + |

| Citric Acid | + / + | + / + | + / + | + / - | o / o |

| Copper Sulphate | + / + | - / - | + / + | + / + | o / o |

| Detergents | + / o | + / o | + / + | + / + | + / + |

| Diesel fuel | + / + | o / o | + / o | + / + | + / + |

| Ethanol | + / + | + / + | + / + | + / + | + / + |

| Ethylene Glycol | + / + | + / + | + / + | + / o | + / + |

| Ferric Chloride | + / + | - / - | + / + | - / - | - / - |

| Formaldehyde (Formalin) | + / + | o / o | + / + | + / + | + / + |

| Formic Acid | + / o | - / - | + / + | - / - | + / o |

| Fruit Juice | + / + | + / + | + / + | + / - | + / + |

| Gasoline | - / - | - / - | - / - | + / + | + / + |

| Glycerol (Glycerin) | + / + | + / + | + / + | + / + | + / + |

| Hydrogen Peroxide, dilute | - / - | - / - | + / + | o / - | + / + |

| Lactic Acid | + / + | o / - | + / + | + / - | + / o |

| Methanol | - / - | o / - | + / + | + / + | + / + |

| Milk | + / o | + / + | + / + | + / + | + / + |

| Mineral Oil | + / + | + / + | + / + | + / + | + / + |

| Nitric Acid, dilute | - / - | - / - | + / + | - / - | + / o |

| Nitrobenzene | - / - | - / - | + / + | + / - | + / + |

| Phosphoric Acid, dilute | + / + | - / - | + / + | + / - | o / - |

| Propanol (IPA) | o / - | + / + | + / + | + / + | o / o |

| Silver Nitrate | + / o | o / - | + / + | + / - | + / + |

| Soaps | + / + | + / + | + / + | + / + | + / + |

| Sodium Hydroxide, dilute | + / + | o / - | + / + | + / + | + / + |

| Sulphuric Acid, dilute | o / - | - / - | + / + | o / - | o / - |

| Urine | + / + | + / + | + / + | + / + | + / + |

| Vegetable Oil | + / o | + / + | + / + | + / + | + / + |

| Water | + / + | + / o | + / + | + / + | + / + |

| Water, Sea-, Salt- | + / + | + / o | + / + | + / + | - / - |

The above mentioned data is intended only as a guide for chemical compatibility. We do not assume any liability for the accuracy of the information. It is strongly recommended that users perform their own tests to determine suitability of material.

Magnets

We provide assistance to select the suitable magnet for your sensor application. Please take a look at our overview of prime magnet materials available.

Material Grades | Remanence | Coercivity | Energy Product | Operating | ||

Br | HcB | HcJ | (BH) max. | max. | ||

mT | kA/m | kA/m | kJ/m3 | °C | ||

NdFeB | N30 | 1105 | 836 | 955 | 235 | 80 |

N30H | 1105 | 836 | 1274 | 235 | 120 | |

N30SH | 1100 | 836 | 1512 | 239 | 150 | |

N33EH | 1185 | 828 | 955 | 275 | 180 | |

N35 | 1185 | 828 | 955 | 275 | 80 | |

N35H | 1190 | 828 | 1274 | 275 | 120 | |

N35SH | 1190 | 828 | 1512 | 275 | 150 | |

N40SH | 1260 | 844 | 1512 | 314 | 150 | |

N45 | 1350 | 840 | 955 | 354 | 80 | |

SmCo5 | S20 | 875 | 617 | 1194 | 159 | 250 |

Sm2Co17 | S24H | 975 | 724 | 1433 | 183 | 300 |

S28H | 1065 | 724 | 1433 | 215 | 300 | |

AlNiCo | A500 | 1281 | 50 | 52 | 40 | 500 |

Ferrit | Y10 | 215 | 143 | 203 | 8 | 250 |

Y30BH | 390 | 229 | 231 | 29 | 300 | |

Y35 | 410 | 183 | 167 | 31 | 300 | |

Bonded Ferrit | FB1 | 240 | 171 | 225 | 11 | 80 |

Bonded NdFeB | BN8 | 575 | 378 | 1035 | 64 | 150 |

Magnet Glossary

Anisotropic Magnet material having a preferred direction of magnetic orientation

Bonded Magnets Magnet powders mixed with polymer carrier; mechanical properties reach from elastic to hard; penalty of bonded material is a "weaker magnet" compared to non-bonded material

Coercivity Hc [kA/m] Demagnetizing force necessary to reduce polarisation J (HcJ) or induction B (HcB) to zero

Curie Temperature Temperature at which a magnet is totally demagnetized

Energy Product BH max [kJ/m3] Point on the second quadrant of the hysteresis loop at which the product of induction B and magnetizing force H reaches a maximum; describes the "strength" of magnet material

Gauss Unit of magnetic flux density in the CGS system (1 Gauss = 10-4 Tesla)

Isotropic Magnet material with no preferred orientation; can be magnetized in any direction

Magnet Pole "Output" of the magnetic flux

Oersted Unit of magnetizing force in the CGS system (1 Oersted = 0.0796 kA/m)

Remanence Br [mT] Residual induction in magnet material after being magnetized to saturation

Tesla Unit of magnetic flux density in the SI system (1mT = 10 Gauss)

Interactive Reed Switch

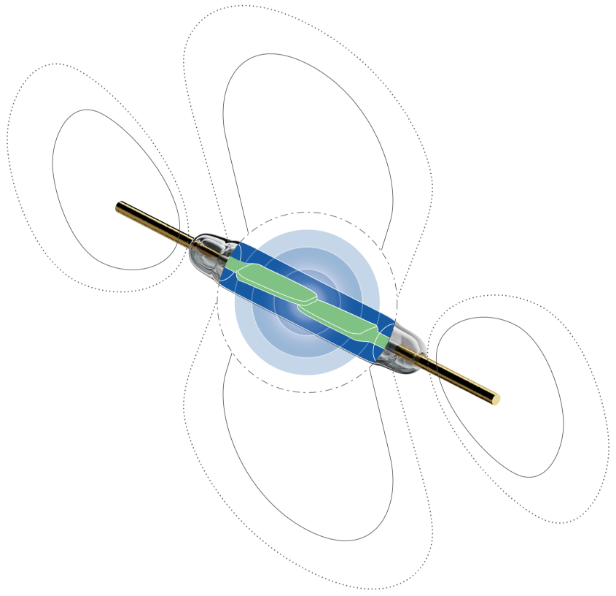

Test the different Reed Switch actuation options and see how a Reed Switch works - with our interactive Reed Switch tool!